-

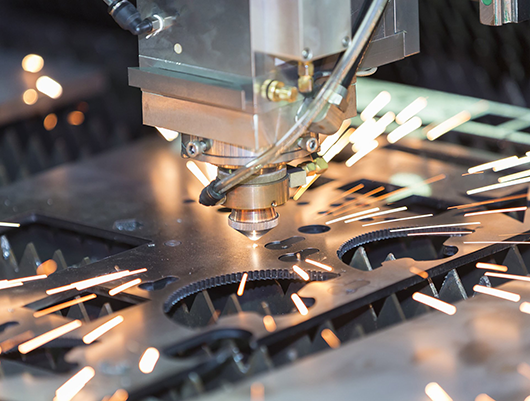

Cutting services

It offers metal cutting services. Our own production base, modern high-precision equipment allows us to efficiently cut rolled products made of galvanized, high-alloy, stainless steel, aluminum, copper, brass.

-

Grinding works

Metal grinding is a mechanical method of precise abrasive processing of elements made of materials of maximum hardness (steels, cast iron, carbon alloy) to ensure a given accuracy and the necessary surface roughness. In particular, grinding is a type of metal cutting with abrasive particles of grinding equipment, each of which performs the function of a micro-cutter, under the action of which the particles of the material are removed.

-

Hole processing

The processing of a hole in a metal is a technological procedure, the main task of which is to bring the excavation of a particular product to a certain configuration with specified parameters. Also, this service, which is carried out, implies bringing the internal coating of the made recesses to a certain roughness index. Moreover, a hole in the metal, which is to be processed in one of the possible ways, can be obtained not only by drilling rolled metal, but also by pouring, punching and other technologies.

-

Protective metal coatings

Wear and corrosion are the main causes of damage to car components and metal structures. In view of this, special attention is paid to increasing the service life and restoring the working bases of various metal parts. Protective metal coating of metal is one of the most reliable ways.